Dimensional Measurement, Inc. (DMI) offers A2LA accredited Surface Roughness Measurement, Calibration (2D Surface Analysis) for your parts at our facility in Wixom, Michigan. Our ISO 17025 accredited certification includes surface analysis and testing, which can provide a valuable evaluation for warranty and product issues, such as:

Dimensional Measurement, Inc. (DMI) offers A2LA accredited Surface Roughness Measurement, Calibration (2D Surface Analysis) for your parts at our facility in Wixom, Michigan. Our ISO 17025 accredited certification includes surface analysis and testing, which can provide a valuable evaluation for warranty and product issues, such as:

- Wear verification

- Noise or mating part irregularities

- Seal leaks

- Failure analysis

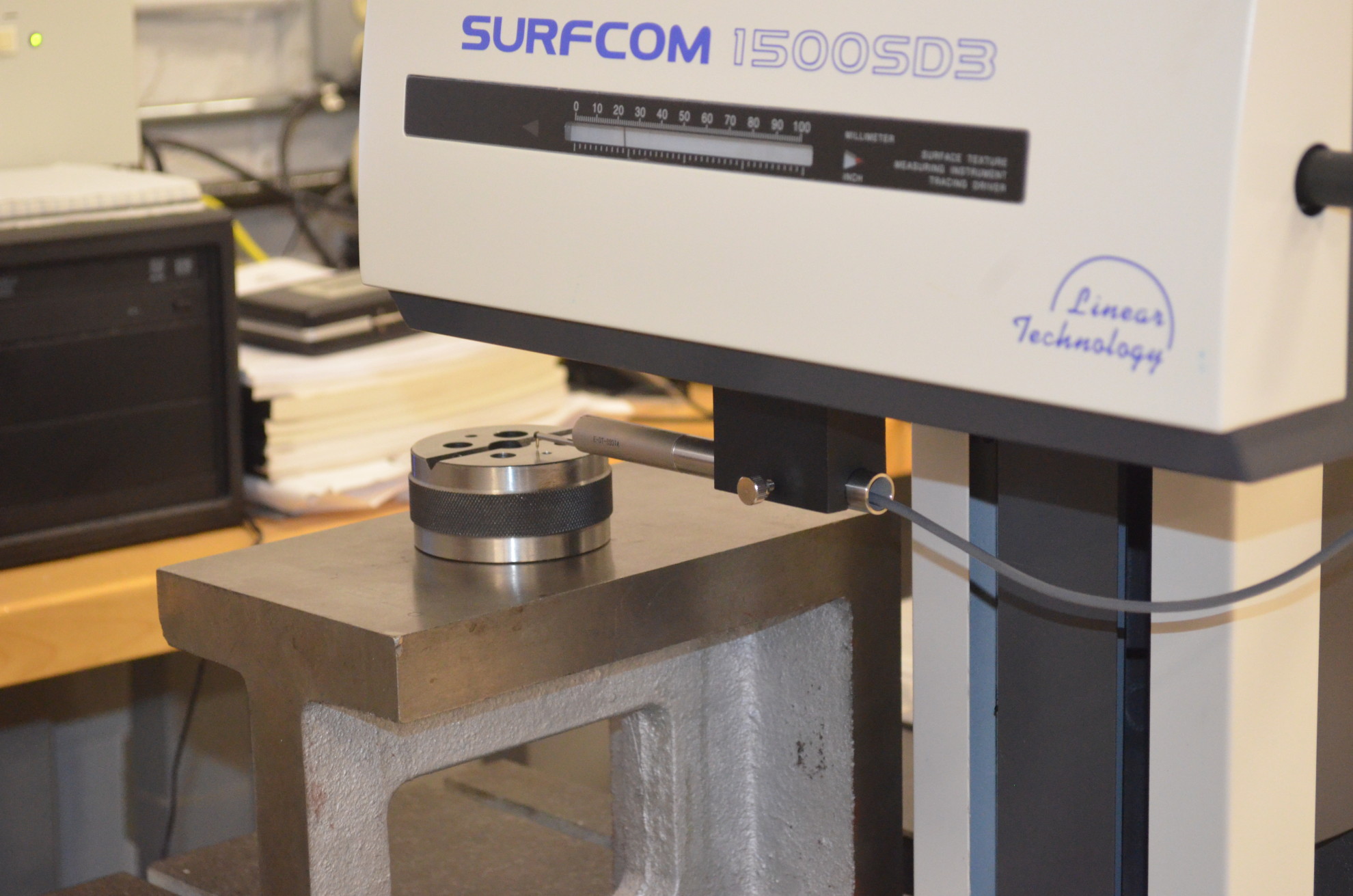

Surface analysis is the traditional method of surface finish measurement using information gained from a trace acquired by running a diamond tipped stylus over the subject part being tested. This method of surface analysis is widely used by most industry segments. DMI’s Zeiss surface roughness profilometer is capable of surface finish measurement using special form styli (measuring tips) to allow access into areas on parts that are not otherwise accessible with standard measuring equipment. DMI can provide Profilometer measurement of plastics and soft materials which can be provided by using a special low pressure sensor.

There are dozens of different surface finish parameters that can be reported, some of the more common ones are:

Ra – Roughness Average

Rz – Average Maximum Height

Rt – Maximum Height of the Surface

Rv – Maximum Valley Depth

Rp – Maximum Peak Height

R Motif – Motif Parameter

DMI’s proficiency with surface measurement allows us to accurately identify the problem at hand, apply standards, and utilize the proper equipment for surface analysis. Resulting data can be displayed in a graphical report.

]Examples of the most popular standards used by DMI to measure surface roughness are:

- ISO 4288 1997: Geometrical Product Specifications (GPS) – Surface Texture: Profile method – Rules and procedures for the assessment of surface texture

- ISO 3274 1996: Geometrical Product Specifications (GPS) – Surface Texture: Profile method – Nominal characteristics of contact (stylus)instruments

- ISO 12085 1996: Geometrical Product Specifications (GPS) – Surface Texture: Profile method – Motif parametersMotif parameters are typically used by French based organizations

DMI can help you make sense of your surface roughness measurement requirements, provide the proper means of surface analysis, and establish the correct parameters necessary to help you qualify sensitive details of your part’s performance.